ABOUT US

We are a purely Czech company. We have a tradition since 1985. Our products work in hundreds of plants from family farms to multi-station farms. In addition to the Czech Republic and Slovakia, we also operate in the Russian Federation, Belarus, Poland, Kazakhstan and Tajikistan.

Our products are universally designed. They can be used very well on a large farm, but also on a small family farm. Each order is handled individually according to the requirements of the farmer.

We develop new products in accordance with the latest technological trends and procedures. At the same time, we always take into account the needs of specific users, their capabilities and the longevity of our products. We consult with experts from universities and research institutes.

Cooperation with the customer does not end with the handover of the finished order, but continues with quality care. Our goal is to create client confidence in our style of work and their maximum satisfaction.

The History

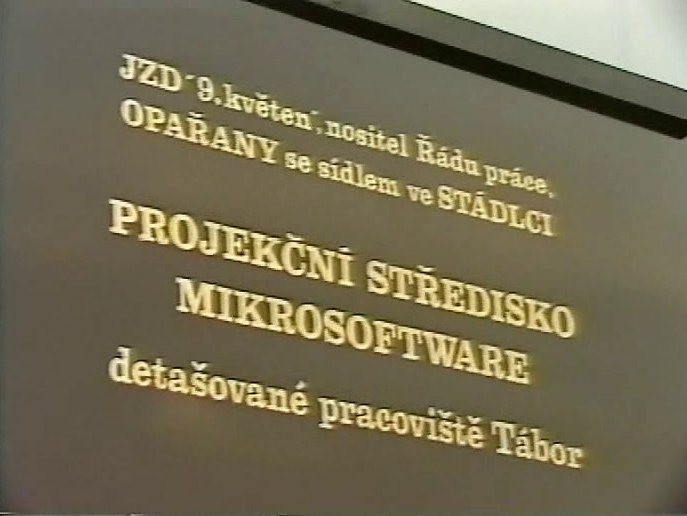

The origins of AGROSOFT date back to 1985, when the Microsoftware Design Centre was established at the JZD 9. květen with its headquarters in Stádlec. It was located in Tábor in Stránského Street as a separate workplace. Programmers and developers worked there. The production facilities were located in Řepč in the JZD complex.

The development of the first software for cattle breeding under the name Agrosoft Skot started in 1985. The development was carried out on the then modern and powerful microcomputers SAPI 1, SAPI 80, Robotron. The programme was written in the Fortran programming language.

Almost at the same time as the development of Agrosoft Skot, the development of a pig management program called Agrosoft Prasata. This program used the same hardware and software background as Agrosoft Skot.

Programové vybavení Agrosoft Skot a Agrosoft Prasata bylo nejprve nasazeno pouze v rámci JZD Opařany. Následně bylo nabídnuto i dalším zemědělským podnikům. V roce 1988 měly oba programy dohromady již 200 platících zákazníků.

The Agrosoft Skot and Agrosoft Prasata software was initially used only within JZD Opařany. It was then offered to other farms. By 1988, the tw software products together had 200 paying customers.

The development of stable technologies began in 1986. The first to be developed was the automatic feeding box for dairy cows (AKB). The development was carried out in cooperation with STS Opava, which supplied the electronic animal identification. The first installation of the feed box system was put into operation at VKK Lomec in 1988. In June 1989, the forecourt in Řepč and the cowshed in Opařany for 600 dairy cows were inaugurated with the then most modern elements of free-range technology, including automatic feeders. Five years later, 40 farms were using automatic feeders.

Independence

After November 1989 JZD was restructured. As part of these changes, the Microsoftware Design Centre became independent in 1992 and started operating as an independent company under the name AGROSOFT Tábor s.r.o. The newly established company is located entirely in the original premises in Tábor, Stránského 2255. The workplace in Řepč was no longer used. The main focus was still the development and distribution of software for agricultural practice, development, production and sale of technological equipment for cattle and pig breeding.

Over time, however, the original premises became increasingly unsuitable and the building fell into disrepair. Mainly for these reasons, the company moved to Jistebnice in 2007, where it was located in rented premises on the premises of Farmtec a.s..

In 2011, the company found suitable premises for its activities in Tábor, at Údolní 2930. The company moved almost immediately and has been located at this address ever since.

Technical progress

The development staff of our company has always sought the best compromise between practical requirements, price of technology, modern solutions, availability, long-term and easy maintenance, etc. The technical readiness of the customers and the habits of the users also have a significant influence.

In the early 1990s there was a complete switch from the original SAPI 8-bit computers to PC-XT and then immediately to PC-AT compatible computers. This was accompanied by a move to the DOS operating system. The existing software was updated and modified to be compatible with the new hardware technologies and the new operating system. In particular, the FORTRAN programming language was abandoned and the new relational database system REDAP was introduced. For the user, this meant a significant increase in programme performance, a reduction in the time required to carry out more demanding operations and a welcome increase in the comfort of using the programme.

In 1995 came the first graphical operating system, Windows 95, and another major update of all the programmes in development and their adaptation for use with the new operating system. Of course, the new software had already been developed to be compatible with this new operating system.

The original STS Opava domestic electronic identification system has been replaced by the modern TIRIS identification system supplied by Texas Instruments. Identification transponders and readers TIRIS have been manufactured using modern processes, with better quality and significantly smaller size. They provide reliable, accurate and fast livestock identification at an affordable price. We are already developing multi-platform software to make them fully functional on Windows, Linux and Mac. At the same time, we are developing applications that support modern means of communication.

The Present

Our core programme is software and robust electronically controlled technologies. The traditional Agrosoft SKOT programme has its place on the market. Major users of this programme include ZD Krásná Hora nad Vltavou and ZD Opařany. We have expanded our product portfolio with a system for monitoring and controlling the microclimate in the stable. We use thermal cameras to monitor hoof health. For Farmtec, we have developed a complete system for managing stable technology and supporting cattle breeding – Farmsoft. This consists of electronic identification of dairy cows, data collection from the milking parlour, selection gates, AKBs and monitoring of movement activity. The Vitalimeter 5P not only monitors the cow’s movement, but also the time spent eating and ruminating. The Farmsoft system is offered to the user as a complete system or as a subassembly of separate technological parts (e.g. core dosing by AKB).

Together with the University of South Bohemia in České Budějovice, Farmtec a. s. and ZD Krásná Hora nad Vltavou a.s., we have successfully completed the research task QJ1210144. The full title of the project is Development of a New Information System and Applied Technological and Organisational Innovation of Control Systems in Dairy Cattle Breeding to Increase the Competitiveness of Breeders and Animal Products and Animal Welfare. The results of this project – microclimate parameters, new design of AKD, pass-through weighing system, motion activity monitoring function, control software algorithms – were used in the development of the Farmsoft system. We are still cooperating with the Faculty of Agriculture and Technology, we have ongoing projects for monitoring the quality of milking milk, automated system for monitoring stable indices and animal identification by image analysis. The most extensive project is the development of a robotic arm for conventional milking parlours.

In addition to the development of software, hardware and identification, we have a quality group for the implementation of the above systems, including zootechnical and operational consulting. Another group deals with the installation, maintenance and repair of technological systems, mainly controlled by electronic systems (milking robots, milking machines, milking parlours and milking systems, etc.) of our own and foreign origin.

The Future

Our aim is to attract new satisfied customers and retain existing ones. This means providing high quality, practical products at affordable prices, together with the highest level of service. Responding to user suggestions. Keeping abreast of the latest developments in breeding and husbandry and trends in agricultural technology and incorporating them into our systems, whether in software, hardware or communication technology. We are gradually turning our company into a research and development (R&D) system. This is used to develop individual devices with the aim of patenting them and then selling them.

Our cooperation with the Faculty of Agriculture and Technology at the University of South Bohemia has reached a higher level. We have several projects underway where we are creating Agriculture 5.0 with the help of artificial intelligence elements and the inclusion of robotic and fully automated systems. Industry is only at the level of 4.0, in agriculture we work with living creatures and we are affected by climatic conditions, and these are factors that industrial production lines do not affect. The use of new robotic and fully automated systems in primary agricultural production should also attract new young workers.